Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

News

cold rolled steel coil manufacturers suppliers

Cold Rolled Grain Oriented (CRGO) silicon steels are used for laminations of the Power Transformers. Cold Rolled Grain Oriented (CRGO) sheets will have superior magnetic properties in the direction of rolling. The crystals are aligned in the direction by cold rolling followed by heat treatment process.

Properties of CRGO Steel

It is a soft magnetic material and has the following properties:

- High magnetic permeability.

- Reduced magnetostriction.

- High resistivity.

- High stacking or laminating factor allows compact core designs.

- Low losses.

Grades of CRGO Steel

The early grades of steel were known as M7(0.7watts /lb at 1.5T/60Hz) and M6(.6watts/lb at 1.5T/60Hz).

Similarly, M5 M4 and M3 grades were developed in the late sixties.

A new material called Hi-B has a remarkable degree of orientation and is 2 – 3 grade better than conventional CRGO steel products.

Application of CRGO Silicon Steel as Transformer Core

CRGO grade steel mainly finds applications as core material for power transformers and distribution transformers.

- High magnetic permeability leads to low excitation currents and lower inductions.

- Low hysteresis and eddy current losses.

- Excellent lamination factor leads to better and compact designs and hence low material required.

- High knee saturation characteristics.

- Very low level of magnetostriction leads to noise reduction.

- Enhances ease of winding and improves productivity.

| TYPICAL PHYSICAL PROPERTIES | |

|---|---|

| Electrical Resistivity | |

| 20°C (68°F) | 48 Microhm-cm |

| Thermal Coefficient of Resistivity | |

| 20-145°C (70-300°F) | 0.047 Microhm-cm/°C |

| Thermal Conductivity | |

| 20-600°C 1100°F |

70- 0.0715 Cal/cm ▪Sec▪°C/cm 207.4 Btu/ft ▪Hr▪°F/ln |

| Heat Capacity | 0.12 Cal/g/°C(Btu/lb/°F) |

| Thermal Expansion | |

| 20-100°C | 11.9 ▪10 ▪cm/cm/°C |

| 20-300°C | 12.9▪10 ▪cm/cm/°C |

| 20-500°C | 13.6▪10 ▪cm/cm/°C |

| 20-700°C | 14.2▪10 ▪cm/cnVC |

| 20-900°C | 14.6▪10 ▪cm/cm/°C |

| 20-1065°C | 15.3▪10 ▪cm/cm/°C |

| Density | |

| 7.65 g/cm3 | 0.28 lbs/ln3 |

| Saturation Induction | |

| 20350 Gauss | 2.035 Tesla |

| Curie Temperature | |

| 730°C (1350°F) | |

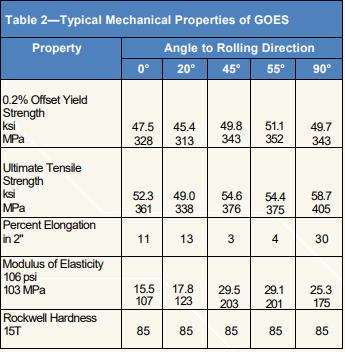

Typical Mechanical Properties of GOES

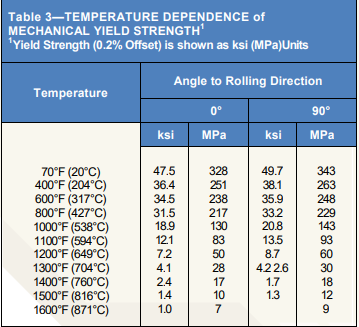

Temperature Dependence Of Mechanical Yield Strength

JFY Grain-Oriented Electrical Steel (GOES) is processed under carefully controlled conditions to develop optimum magnetic characteristics in the rolling direction. Cold-Rolled Electrical Grain Oriented Steel develops low core losses at high inductions when used as core material in designs with the flux path parallel to the rolling direction. These low losses at high inductions are attained with low exciting currents because of the excellent high induction permeability of Cold-Rolled Electrical Grain Oriented Steel.

In addition, the normal operating inductions for Cold-Rolled Electrical Grain Oriented Steel are sufficiently below the magnetic saturation of the material to allow a comfortable margin of safety in most designs. Processing of Cold-Rolled Electrical Grain Oriented Steel is carefully controlled in order to achieve a very high stacking factor for the core material. This stacking factor often exceeds 95 percent of the theoretical maximum.

The high usable magnetic induction of Cold-Rolled Electrical Grain Oriented Steel, along with the high stacking factor, allow compact core designs requiring the minimum amount of material to be used in the windings surrounding the core. This contributes to low losses, not only in the core (no load losses), but also allows for minimum load losses or winding losses in the transformer.

JFY Cold-Rolled Electrical Grain Oriented Steel also offers low manufacturing costs for transformer cores. Cold-Rolled Electrical Grain Oriented Steel may be processed into conventional core designs and is available in a wide variety of widths ranging from 3 inches to 34 inches (7.6 cm to 86.4 cm). Cold-Rolled Electrical Grain Oriented Steel can be formed by conventional methods. Slitting, cutting to length, winding, and stacking may all be accomplished using conventional core processing. Stress relief annealing, where required, can also be accomplished using conventional techniques.