Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

News

Essence of Custom Cold Rolled Grain Oriented Electrical Steel

In the world of electrical engineering and manufacturing, the Custom Cold Rolled Grain Oriented Electrical Steel stands as a paragon of precision and efficiency. This advanced material is the backbone of many electrical applications, from transformers and generators to inductors and reactors. Its unique properties make it an indispensable component in the pursuit of energy efficiency and performance. Let's delve into the intricacies of this remarkable material and explore its significance in modern technology.

The Marvel of Grain Orientation:

Custom Cold Rolled Grain Oriented Electrical Steel is characterized by its high silicon content, typically around 3%. This silicon enrichment significantly enhances the steel's magnetic properties, particularly its permeability and resistance to electrical conductivity. The grain orientation process ensures that the steel's crystal structure is meticulously aligned, optimizing its magnetic properties in the rolling direction. This alignment is crucial for applications requiring low core losses and high permeability under high flux densities.

Applications of Custom Cold Rolled Grain Oriented Electrical Steel:

1. Transformers:

Custom cold rolled grain oriented electrical steel is commonly used in the manufacturing of transformers, including power transformers, distribution transformers, and instrument transformers. It is used in the core of the transformer to efficiently transfer electrical energy.

2. Motors and Generators:

This type of electrical steel is also used in the construction of motors and generators, where it helps to reduce energy losses and improve the overall efficiency of the equipment.

3. Inductors and Chokes:

Custom cold rolled grain oriented electrical steel is used in the production of inductors and chokes, which are essential components in electronic circuits for filtering and regulating electrical currents.

4. Magnetic Circuits:

It is used in various magnetic circuits, such as magnetic cores in sensors, actuators, and other electromagnetic devices.

Benefits of Custom Cold Rolled Grain Oriented Electrical Steel:

1. High Magnetic Permeability:

Custom cold rolled grain oriented electrical steel has high magnetic permeability, which allows for efficient magnetic flux transfer and reduces energy losses in electrical equipment.

2. Low Core Losses:

This type of electrical steel has low core losses, making it ideal for applications where energy efficiency is crucial, such as transformers and motors.

3. Improved Magnetic Properties:

Custom cold rolled grain oriented electrical steel has improved magnetic properties compared to other types of electrical steel, resulting in better performance and reliability in electrical equipment.

4. Reduced Eddy Current Losses:

The grain orientation of the steel helps to reduce eddy current losses, which can further improve the efficiency of electrical equipment.

5. Consistent Performance:

Custom cold rolled grain oriented electrical steel is manufactured to strict specifications, ensuring consistent performance and reliability in various applications.

The Advantages of Customization:

Customization is the key to optimizing performance in specific applications. By tailoring the thickness, surface finish, and other specifications of the Custom Cold Rolled Grain Oriented Electrical Steel, manufacturers can ensure that the material meets the precise needs of their products. This customization leads to improved efficiency, reduced material waste, and enhanced product performance.

Market Trends and Demand:

The demand for Custom Cold Rolled Grain Oriented Electrical Steel is on the rise, driven by the growing focus on energy efficiency and the expansion of renewable energy infrastructure. The market is also influenced by the increasing adoption of electric vehicles and the need for high-performance materials in consumer electronics. As the world moves towards sustainable energy solutions, the role of this steel in facilitating efficient power transmission and conversion becomes more critical.

Manufacturing Process:

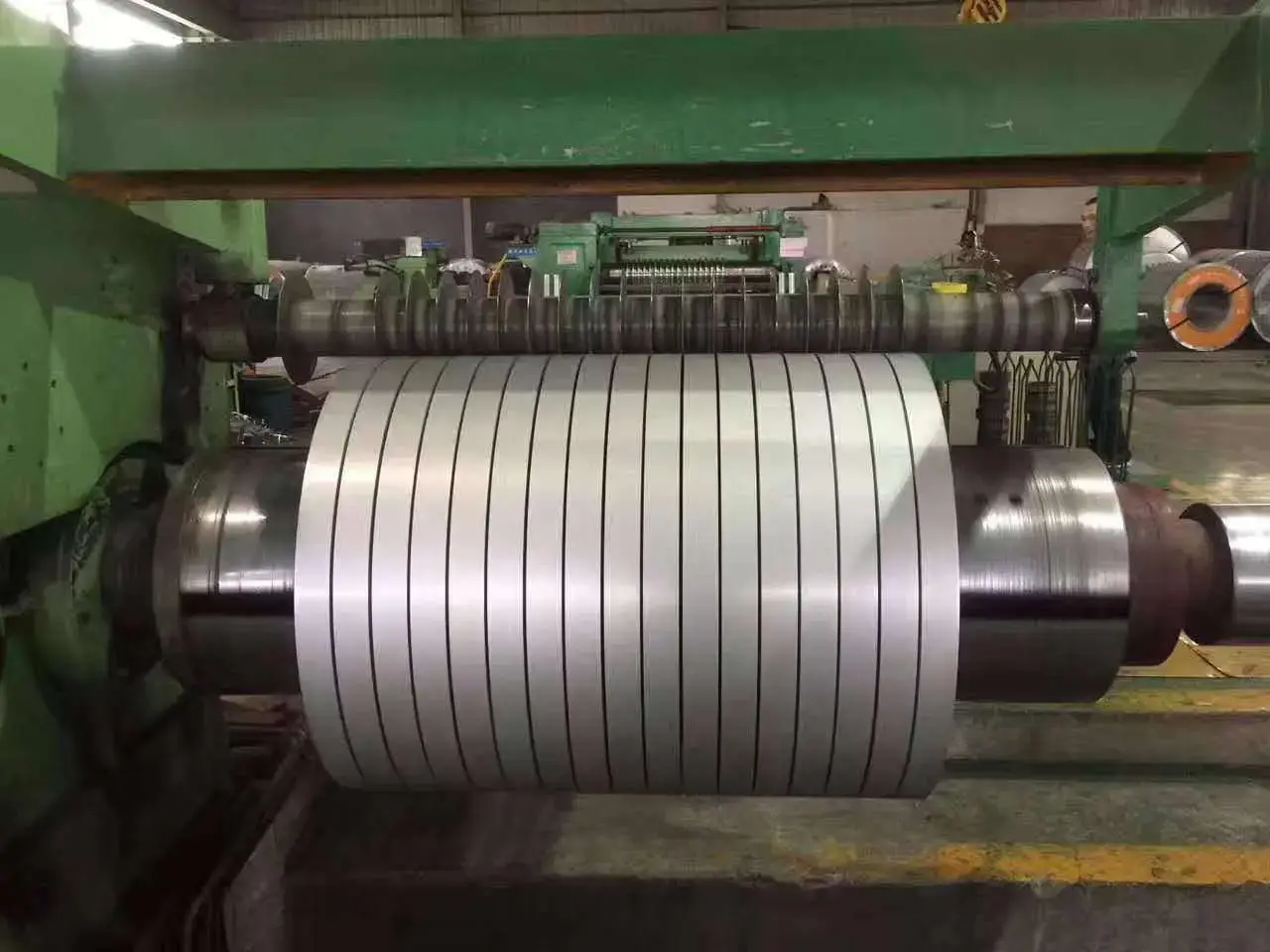

The manufacturing process of Custom Cold Rolled Grain Oriented Electrical Steel is a testament to modern metallurgical advancements. It involves a series of meticulous steps, including BOF or basic oxygen furnace steelmaking, secondary refining, continuous casting, slab reheating, hot rolling, stress-relief annealing, cold rolling, secondary recrystallization annealing, and heat flattening coating. Each step is carefully controlled to ensure the final product's exceptional quality and performance.

Surface Coatings:

To further enhance the steel's performance, various surface coatings are applied. These coatings, such as C-2 and C-5, provide insulation, improve resistance to rust and oxidation, and contribute to the steel's overall durability. The choice of coating depends on the specific application requirements, with some coatings offering better resistance to high temperatures and stress-relief annealing.

Conclusion:

Custom Cold Rolled Grain Oriented Electrical Steel is a cornerstone material in the electrical industry, offering a perfect blend of performance, efficiency, and customization. Its unique properties and the ability to tailor it to specific applications make it an ideal choice for a wide range of electrical equipment. As the world continues to demand more efficient and sustainable electrical solutions, the importance of this steel will only grow, solidifying its place as a key component in the future of energy management .