Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

News

electrical steel laminations manufacturer suppliers

Electrical steel (E-steel, lamination steel, silicon electrical steel, silicon steel, relay steel, transformer steel) is an iron alloy tailored to produce specific magnetic properties: small hysteresis area resulting in low power loss per cycle, low core loss, and high permeability.Electrical steel is usually manufactured in cold-rolled strips less than 2 mm thick. These strips are cut to shape to make laminations which are stacked together to form the laminated cores of transformers, and the stator and rotor of electric motors. Laminations may be cut to their finished shape by a punch and die or, in smaller quantities, may be cut by a laser, or by wire electrical discharge machining.

We live our daily lives surrounded by many types of electrical equipment, such as washing machines and air conditioners. Electrical steel sheets play an important role in this kind of electrical equipment, converting electricity to magnetism, and then into working energy.

In recent years, high-performance and high-efficiency electrical equipment is in strong demand from the viewpoint of environmental protection and reduction in CO2 emissions. Using the world’s most advanced technology, JFY Shanghai Industries Corporation delivers quality electrical steel sheets while contributing to the conservation of the global environment.

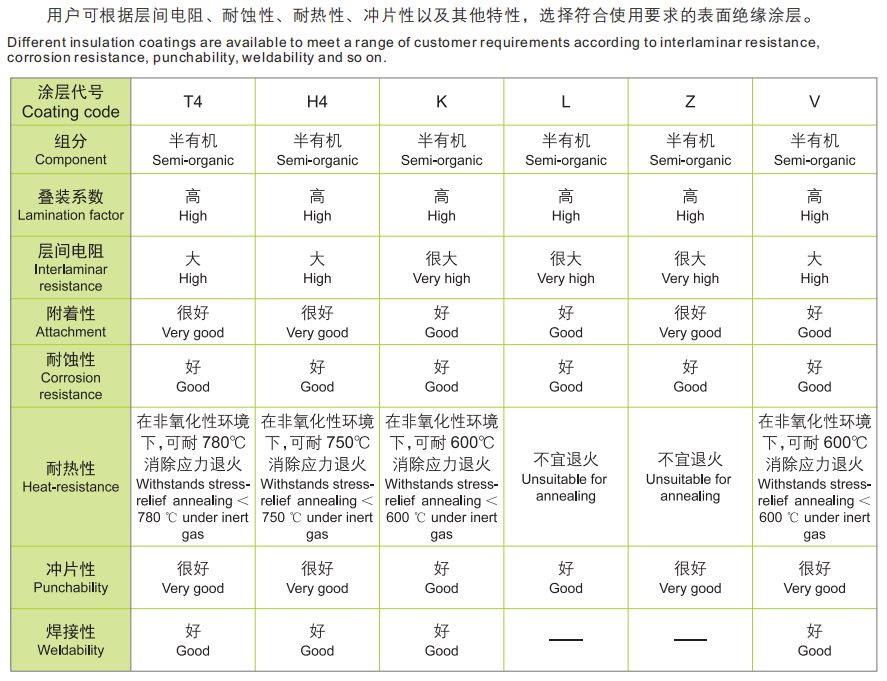

An electrical steel sheet is a functional material used as an iron core material* for electrical equipment. An iron core material must have excellent magnetic properties. For this reason, an electrical steel sheet has characteristics not shared by other regular steel sheets. For instance, an insulating coating is applied to the surface of electrical steel sheets, and impurities in electrical steel sheets (carbon, nitrogen, sulfur, etc.), which deteriorate magnetic properties, are reduced to the limit.

※ An iron core material: A current flow in a conductor coil causes a magnetic field because of the electromagnetic principle. Using the electromagnetic principle, many types of electrical equipment, transform electricity to magnetism and generate a working energy. An iron core material is inserted into the coil to increase the magnetic force.

Types and applications of electrical steel sheets

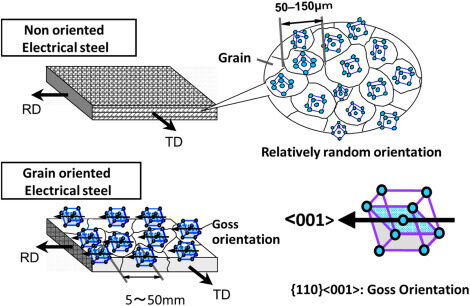

There are two types of electrical steel sheet: grain-oriented electrical steel sheet and non-oriented electrical steel sheet, and they are used for different applications.

●Grain-oriented electrical steel sheet

A steel sheet with excellent magnetic properties only in one direction (the rolling direction) of the steel sheet. It is mainly used for transformers.

●Non-oriented electrical steel sheet

A steel sheet with almost uniform and excellent magnetic properties in all directions of a steel sheet. It is mainly used for motors.

Basic properties of electrical steel sheets

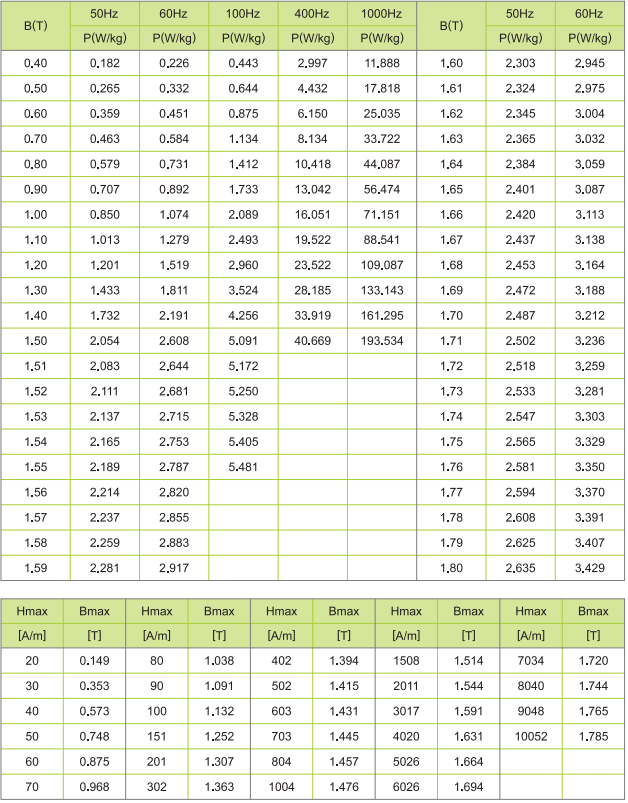

The performance of electrical steel sheets is expressed by two types of magnetic property: magnetic flux density and iron loss.

●Magnetic flux density

An indicator for the ease of magnetization. The higher the magnetic flux density of a material, the higher the magnetic force that can be obtained from it at a constant current, and so, the higher the power that can be obtained.

●Iron loss

An indicator for the magnitude of the loss of energy caused by the conversion of electric energy to magnetic energy. The smaller the iron loss of a material, the smaller the energy loss, and so energy savings can be achieved.

Recommended Applications

Application of electrical steel in automobile

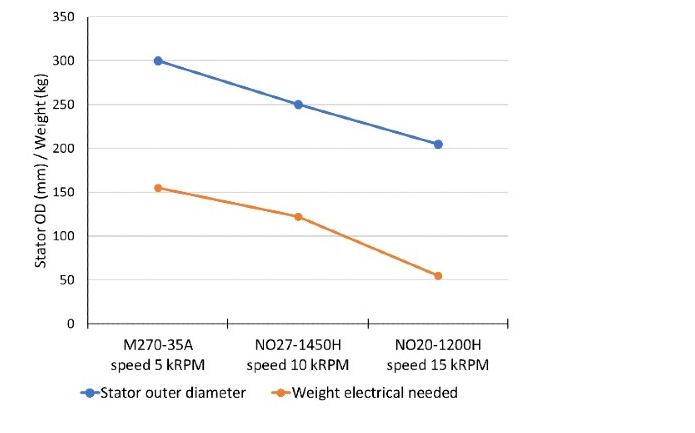

Thin gauge electrical steels make it possible to make electric motors and generators with very high rotating speed. A standard 2-pole motor connected to the 50 Hz grid rotates at approximately 3000 rpm depending on motor type. Rotating at speeds of 10000 rpm or higher enable much higher power from a motor of the same size as the standard

frequency motor. Equally these higher rotational speeds facilitate the delivery of a much smaller motor with the same power. The latter is demonstrated in the figure below in which the use of thinner electrical steel allows motors to be smaller, using less steel, and still obtaining the same power and efficiency.

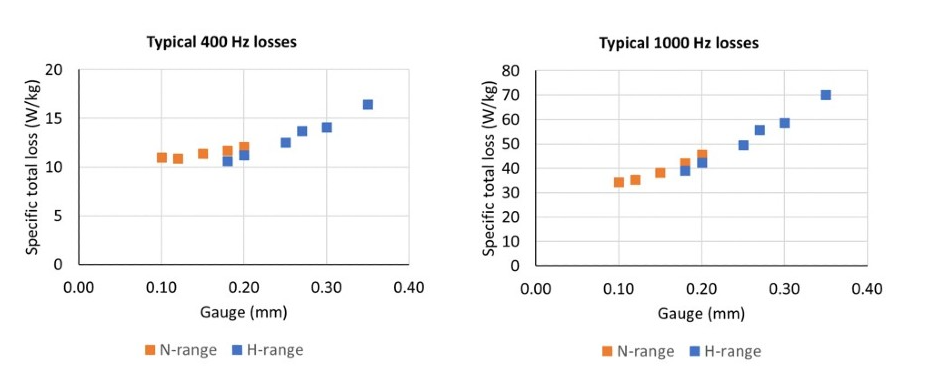

High frequency losses

To maintain high motor efficiency at high speeds, the steel used in the motor needs to have low magnetic losses at high frequencies. At these frequencies the total losses are dominated by eddy current losses, which are proportional to the strip thickness squared and inversely proportional to the electric resistivity of the strip. Thus, thin gauge, in combination with high silicon and aluminium content in the steel (increases resistivity), are needed for low loss at high frequencies.

electrical steel Electromagnetic Property Curves